- Adjusted the timing

- Partially fixed misfiring problem

- Gained more engine power (timing was way off)

- Figured out how to set timing

For a long time I didn't know what to do, and so kept postponing this. I finally took the plunge this weekend and figured out how to check and adjust timing. Sure enough, the timing was off (as if the misfiring hadn't told me that already).

First off, you'll need some equipment. You'll need a timing gun (see image below), a 12 V automotive source for the timing gun (car battery; from another car if you have an MGB), a 12 mm wrench, and some white-out (with a brush works best).

The 1977 MG B specs state that at idle (850 rpm) the timing mark should be at 5 degrees BTDC (before top dead centre), and for 1500 rpm at 10 degrees BTDC. This could be different on your car, so check before doing anything by reading a service manual. On my car I found the instructions on a lable under the hood (where other emissions info such as spark plug gaps etc is found).

Update: If you use a weber (like I do) you'll need to set idle to 14 BTDC. However this differs from car to car. Mine uses a free-flow Peco exhuast, so 14 is correct for me, but if you still have a catalytic converter you will probably need a lower offset.

Finding TDC is not the most obvious thing on my car. One can generally locate it as the 'odd one out' of the teeth that make up the timing alignment. Usually it's slightly bigger, however note that this differs on MGBs (based on the year they were built). The image above shows the situation on my car, the 'teeth' illustrated by #1 and the notch in the front wheel by #2. I used white-out to make them more clear. TDC is - I guessed correctly - the right most tooth. As per the specs of the car, at idle I need to be at 5 degrees BTDC (the 2nd tooth from the right), and at 1500 rpm at 10 degrees (centre tooth). All teeth have a 5 degree separation. On some MGBs these teeth are at the bottom of the engine.

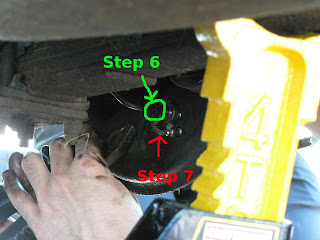

What you do is simply adjust the distributor by turning it left and right till the notch on the wheel lines up with the 5 degree mark on the teeth (at idle). Do this by hooking up the timing gun to spark plug 1, the plug closest to the front of the car (the power cable on mine wasn't long enough to go the the battery, so I had to bring my other car next to it to connect it to a source), and aiming it at the teeth. To turn the distributor loosen the nut holding the sleeve of the distributor to the engine block (#3 in the image below).

And the result is... (idle, 1500 rpm, then idle again)

Note that all this should be done after driving the car around for atleast 5 minutes and everything is at running temperature. The timing marks on my car are on top of the bottom wheel (drive pulley?), but on older models it is often underneath.

Thanks to MG's great battery placement, my timing setup looks like this:

Get a friend to hold the gun.

Get a friend to hold the gun.

UPDATE: I'd like to say that the top picture was a joke, but actually I was just being an idiot. A much easier timing gun setup is: connect the ground lead to a bare part of the frame (for example, that thing that sticks out of the engine where the air pump used to be), and the hot lead to the bottom fuse (ONLY TOUCH THE BOTTOM FUSE). The images below (taken with my phone... sorry) should explain.

Thanks to MG's great battery placement, my timing setup looks like this:

Get a friend to hold the gun.

Get a friend to hold the gun.UPDATE: I'd like to say that the top picture was a joke, but actually I was just being an idiot. A much easier timing gun setup is: connect the ground lead to a bare part of the frame (for example, that thing that sticks out of the engine where the air pump used to be), and the hot lead to the bottom fuse (ONLY TOUCH THE BOTTOM FUSE). The images below (taken with my phone... sorry) should explain.