- Installed new complete Peco exhaust system

- No more exhaust fumes inside the cabin

- Engine can breath freely

The exhaust header, though rusted, was still in great shape. I thought of just sanding it down and repainting it, but had a hard time finding head pipes to connect it to a new exhaust. The rest of the exhaust was in good shape (barely any rust), but seemed clogged. In the end I bought a new Peco header (see image above) with the rest of the exhaust system, a 2-inch straight through system (and a big FU to the EPA). Note that in Maryland classic cars are exempt from state emissions testing, and so removal of the catalytic converter (if there is one, mine did not have one) is legal. This is not the case in California, where pretty much any exhaust or emissions modification is illegal. So check your state regulations to make sure it is as cool as Maryland :-) (if you're in a southern state or Michigan, you're good to go).

The exhaust header, though rusted, was still in great shape. I thought of just sanding it down and repainting it, but had a hard time finding head pipes to connect it to a new exhaust. The rest of the exhaust was in good shape (barely any rust), but seemed clogged. In the end I bought a new Peco header (see image above) with the rest of the exhaust system, a 2-inch straight through system (and a big FU to the EPA). Note that in Maryland classic cars are exempt from state emissions testing, and so removal of the catalytic converter (if there is one, mine did not have one) is legal. This is not the case in California, where pretty much any exhaust or emissions modification is illegal. So check your state regulations to make sure it is as cool as Maryland :-) (if you're in a southern state or Michigan, you're good to go).Update: It has been brought to my attention that removing the catalytic converter is illegal by federal law. Though Maryland is not going to check (assuming you have historic tags), you would apparently still be breaking the law if you remove the converter. A car must always retain its originally installed emissions regulation equipment, even if it fails (!). So draw your own conclusions...

There are several considerations when purchasing an exhaust system, but it generally boils down to whether you want a comfortable or a sporty ride. My Peco system is incredibly loud, and after a short drive my ears were ringing (this will probably improve when I put in sound insulation). It only has the one straight-through muffler, so not really ideal for comfortable riding. If you're looking for a comfortable ride you'll need a decent muffler or a 2-muffler setup (more common on the MGB). If you're a tree-hugger you'll also want to throw in a cat convertor.

When picking a header one should pick one with the least amount of curves, thus improving the flow of gasses. More angles mean a slower flow, though this is generally a very modest decrease. On the MGB there are only 3 exhaust ports for a 4 cylinder car, which seems wrong. This was a conscious choice by the engineers to save manufacturing costs, but was designed in such a way that with it shouldn't impede exhaust fumes too much, however, efficient expulsion of those fumes is very important. The centre two exhaust valves are connected (the so-called 'siamese' system) and go out through one pipe, so naturally that pipe should be larger than the other two (which each serve one valve respectively). The Peco header has a larger centre port which merges with the other two towards the end of the pipe, thus enabling a better flow of exhaust fumes. There are MGB engine upgrades available that allow for four intakes on one side and four exhausts on the other side of the engine (but be prepared for some machining).

A major issue when picking exhaust systems for the MGB is picking the right setup. Over the years the exhaust and intake system changed many times, so a 1980 MGB will have a completely different setup to a 1965 MGB (and I mean radically different). Later models have catalytic converters (under the hood, not in the back) and different intakes. I would strongly recommend retrofitting your car to the old-fashioned exhaust system as I did, but you will also most likely need to change your carburettor and intake manifold for this. This allows for a better freer flow, and will bring your engine closer to the original 98 hp it once had. Consider the Weber DGV (downdraft) if you do this conversion.

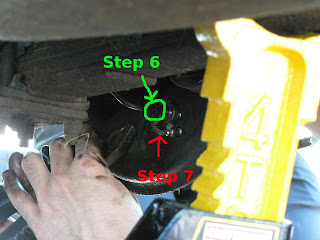

A major issue when picking exhaust systems for the MGB is picking the right setup. Over the years the exhaust and intake system changed many times, so a 1980 MGB will have a completely different setup to a 1965 MGB (and I mean radically different). Later models have catalytic converters (under the hood, not in the back) and different intakes. I would strongly recommend retrofitting your car to the old-fashioned exhaust system as I did, but you will also most likely need to change your carburettor and intake manifold for this. This allows for a better freer flow, and will bring your engine closer to the original 98 hp it once had. Consider the Weber DGV (downdraft) if you do this conversion.The exhaust arrived and I set out to install it, which is a very simple procedure in principle. As it differs on most cars I'm not going to give detailed instructions. Rather, just take a look at your old exhaust and figure out a way of putting the new one in. Don't know what to do? Just start taking it out, and make sure the new exhaust system fits snugly and doesn't move. If it is designed for the MGB it will fit, you just have to keep trying. Here are some tools you will need:

- An electric saw (to saw through pipes and bolts that won't give way)

- A wrench set

- Ramps !!! (I used jack stands and a floor jack, which I do not recommend)

- WD-40

- Muffler clamps (to hold together the pieces of the exhaust system; typically not included)

- A friend to hold stuff

- Patience. Lots and lots of patience. This took me 2 days and was incredibly frustrating.

Now, I was planning on posting a video showing the before and after sounds. Unfortunately my carburettor is acting up, and the damn car won't rev lower than 3000rpm. As I had the intake out anyway I thought I'd rebuild the carburettor. Apparently I did something wrong. As soon as I figure out what I did wrong I'll post it and my solution. In the meanwhile, if anyone has any suggestions....

Now, I was planning on posting a video showing the before and after sounds. Unfortunately my carburettor is acting up, and the damn car won't rev lower than 3000rpm. As I had the intake out anyway I thought I'd rebuild the carburettor. Apparently I did something wrong. As soon as I figure out what I did wrong I'll post it and my solution. In the meanwhile, if anyone has any suggestions....